What is Mass Loaded Vinyl?

Mass Loaded Vinyl (MLV) is a dense rubber-like material commonly used in soundproofing applications. Also known as ‘barrier mat’, MLV is a generic material manufactured by many different companies. Over the course of several decades, various forms of the material have been sold by retailers of soundproofing materials.

MLV is essentially a heavy vinyl sheet which has been impregnated with other materials, such as barium and silicates (sand), to increase the mass and therefore the soundproofing qualities. MLV is commonly sold in weights of 5KG and 10KG per SQM. Although originally conceived as an acoustic pipe lagging for industrial settings, rather than soundproofing in buildings, the material has gradually replaced lead sheets. Lead was often specified in soundproofing applications until environmental concerns created demand for a replacement.

How is MLV Used

Mass Loaded Vinyl is installed in walls and ceilings. The best performance is achieved by fixing it to the studs or joists and then fixing a layer of plasterboard over the top. This allows the MLV to behave as a ‘limp mass’, maximising its ability to absorb noise. It may also be installed between two sheets of plasterboard as a sandwich layer, although this is less effective.

Working With MLV

Due the size and weight of Mass Loaded Vinyl sheets, logistics may pose some challenges. Firstly delivery costs are high and the product is bulky to store. Depending on the size of roll, it can take up to four people to manoeuvre the material on site which is costly in terms of labour time.

Installation is also time consuming and takes multiple people to support the weight of the material whilst it is fixed in place. MLV has to be hand cut around obstacles and every join must be taped to make it airtight before the plasterboard is fixed on top. Some brands are susceptible to tearing during installation which compromises their ability to block sound. This is especially common if the material has been exposed to extremes of temperature.

QuietGlue Pro is supplied in lightweight tubes making it easy to ship on a standard overnight courier service. Installation is transparent by comparison – when installing your second layer of plasterboard, simply dispense two tubes onto the back of the board before screwing it to the wall in the conventional way. For a more detailed explanation, have a read of the QuietGlue Pro Installation Guide.

Acoustic Performance

Despite the number of companies manufacturing Mass Loaded Vinyl, very little test data exists. Most manufacturers quote an STC (Sound Transmission Coefficient – a measure of sound reduction through a structure) of 26 or more for the material tested alone. This tells us very little about how it will perform in a wall or ceiling assembly since STC values cannot be combined. It is interesting to note that a single layer of 12.5mm plasterboard has an STC of 28 – 2 points higher than 5KG MLV. However, when added to an existing stud wall, the performance increases just 3 STC points: from 34 to 37 STC.

Table 1: Comparison of MLV and standard plasterboard (tested in isolation)

| Frequency (Hz) | 125 | 250 | 500 | 1000 | 2000 | 4000 | STC |

|---|---|---|---|---|---|---|---|

| 5KG MLV | 13 | 17 | 22 | 26 | 31 | 36 | 26 |

| 15mm Plasterboard | 16 | 22 | 27 | 31 | 29 | 31 | 29 |

MLV vs. QuietGlue Pro

The following wall drawings and STC values give a clear picture of how Mass Loaded Vinyl compares to QuietGlue Pro in a conventional stud wall.

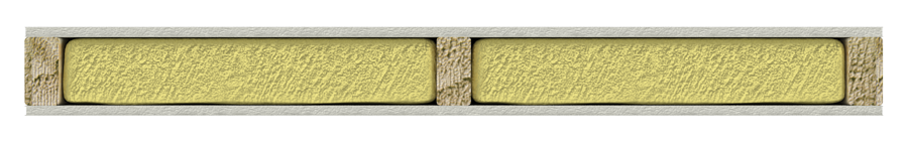

Wall 1

Single layer of 15mm plasterboard on both sides.

Tested STC 34

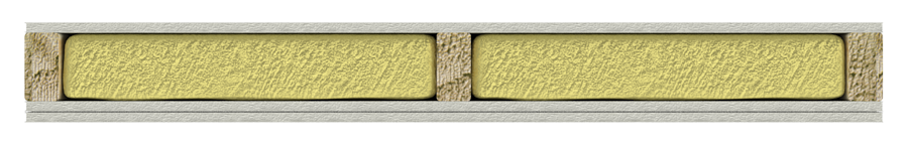

Wall 2

Single layer of 15mm plasterboard on one side.

Double layer of 15mm plasterboard on the other side.

Tested STC 36

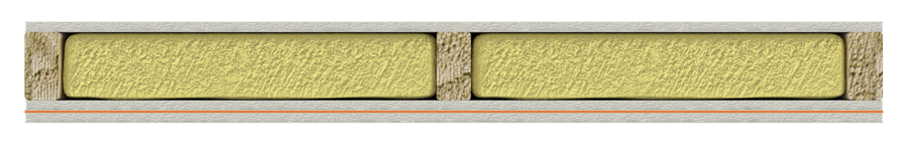

Wall 3

Single layer of 15mm plasterboard on both sides.

5KG per SQM Mass Loaded Vinyl on one side.

MLV fixed directly to studs inside wall cavity for best performance.

Tested STC 43

Wall 4

Single layer of 15mm plasterboard on one side.

Double layer of 15mm plasterboard on the other side.

2 Tubes of QuietGlue Pro between the double layer.

Tested STC 50 (Test number OL10-0839)

In Summary

Mass Loaded Vinyl has been sold for several decades as a soundproofing material. Though not originally intended for use in buildings, MLV can provide limited increases in STC if installed correctly. However, the cost of handling and installing such materials, combined with the potential for complications during or after installation mean MLV is impractical in many scenarios.

When considering overall costs, test data and the science of sound isolation in buildings, it is clear that MLV simply cannot compete with QuietGlue Pro on the basis of price and performance.